Rental Solutions: Reduce rental hassles

Electronic fuel injection helps reduce maintenance, increases reliability.

By Tom Billigen

In the late 1970s, electronic fuel injection (EFI) and power windows were high-end options in the automotive industry — available only on products that could justify the added cost.

|

| On commercial mowers, where engines run for hours on end at a relatively steady rpm, EFI can provide significant fuel savings. |

|

| Unlike carburetors, which can be disassembled and cleaned, the main components of an EFI system need to be replaced if damaged. However, if properly treated, EFI engines can sit for extended periods of time without any issues. |

|

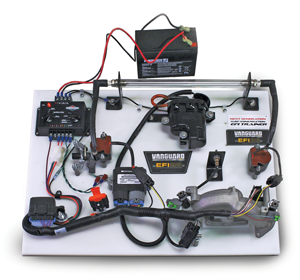

| Briggs & Stratton’s fully functional EFI training board can be prompted by an instructor to display trouble codes. |

Like many high-end options, their price and reliability eventually reached a point where they would become standard on most vehicles. By the late ’90s, nearly every passenger vehicle in the world is powered by an EFI engine, and power windows could be found on all but the lowest price-point models.

While EFI replaced carburetors as the standard for automobiles, it took off rather slowly for small engines due to the cost of initial EFI systems and lack of a proven track record. When something has been working adequately for decades, as carburetors have, talk of change is often met with skepticism.

As cost-effective EFI engines enter the market, skepticism is quickly fading as more professionals experience the benefits of today’s EFI engines.

EFI benefits

In recent years, the buzz of fuel savings as high as 25 percent with EFI caught people’s attention. By creating a near-perfect air-fuel mixture and adjusting the ratio based on load, throttle response and air intake, EFI optimizes fuel efficiency and power in ways a carburetor cannot match.

While fuel savings vary by industry, application and engine family, the 25 percent fuel savings made the reality of ROI more tangible. In the commercial turf industry, for example, where engines run for hours on end at a relatively steady rpm, the opportunity to reap the benefits of these fuel savings became real, fast.

Another enticing benefit of EFI engines is reliable, chokeless starting. While seasoned operators could argue that starting equipment is not a significant problem, contractors tasked with training inexperienced employees may disagree. Difficulty starting machines, flooded engines and the downtime associated with both result in decreased productivity and profits.

Basic service changes

For decades, carburetors have served their purpose. They are inexpensive, do not require a computer for diagnostics and most importantly, every good mechanic is equipped with the tools and know-how to service a carburetor. While this may sound like an argument against embracing the new technology, carburetor repairs are the leading cause of downtime for small engines.

Additionally, most engine components, aside from the fuel system, remain unchanged between carbureted and EFI engines. Comparing apples to apples — similar horsepower models from the same engine family — the fuel filter is often the only difference. EFI engines require more advanced filter media and occasionally have a second filter to prevent any impurities from reaching the fuel injectors. This is necessary because EFI systems force fuel through a high-pressure injector that atomizes the liquid into a fine mist, creating a more volatile mixture with a lower concentration of fuel.

Stale fuel resistance

EFI engines are also more resistant to stale fuel. In EFI engines, fuel is exposed to far less oxygen, helping prevent fuel degradation. Along with being more resistant to stale fuel, EFI engines are also more capable of burning degraded fuel. Their high-pressure injectors atomize the fuel into a mist to create an ideal blend that burns even when fuel is highly degraded. In a carbureted engine, low-volatility fuel is less likely to burn and attempts to start it can result in a flooded engine.

As a general rule, if equipment will sit longer than 30 days, treat the engine with a fuel stabilizer. Despite being more resistant to the adverse effects of stale fuel, it’s still best to stick with the 30-day rule. Unlike carburetors, which can be disassembled and cleaned, the main components of an EFI system need to be replaced if damaged. However, if properly treated, both EFI and carbureted engines can sit for extended periods of time without any issues.

As EFI gains traction in the small engine market, it requires dealers and technicians capable of servicing the engines and the need for specialized training. To successfully address this, manufacturers developed EFI training programs to educate and equip dealers with the needed training tools.

Traditionally, hands-on experience works best for engine training, but is problematic with EFI engines for a number of reasons. Working on actual engines limit instructors since they cannot prompt the engine to generate specific trouble codes. Additionally, transporting and running engines limit where training can take place.

To develop a live, fully operational EFI system without the transportation hassles of actual engines, one manufacturer engineered a fully functional and responsive training board that can respond as if it were attached to a live, running engine. With this program, instructors can prompt real trouble codes, creating a fully operational system that’s easy to transport and can run indoors.

Some manufacturers also have dealer training requirements and certifications in place to ensure engines are backed by the support and parts necessary to keep them up and running. For rental centers, the same often applies, as many operate as unlisted equipment dealers, giving them the same level of support and parts access as traditional dealers.

As more dealers and rental centers become trained to quickly diagnose and repair EFI engines, customers will have much to gain in efficiency and reliability. As sales of equipment with EFI engines increase, more contractors are willing to give EFI a chance.

The future of EFI engines

Currently, EFI is more prevalent on commercial equipment, however, consumer EFI engines exist and manufacturers are working to develop less-expensive consumer options as well as improved open-loop versions to help EFI further expand beyond commercial markets. Some consumer versions under development feature fewer components to simplify the system while offering comparable performance in a cost-effective package.

Eventually, EFI — in one form or another — will find its way into nearly every product segment. But unlike the automotive industry, the carburetor will probably never disappear entirely from outdoor power equipment. Instead, it will likely be relegated to equipment at a lower price point and eventually — similar to hand-crank windows —carbureted engines will be the exception, not the standard.

Tom Billigen is customer education training manager at Briggs & Stratton.

this story originally appeared in the November-December issue of Pro Contractor Rentals magazine. Copyrighted--all rights reserved.