Fix potholes permanently

The JCB Pothole Pro delivers a rapid permanent repair solution.

|

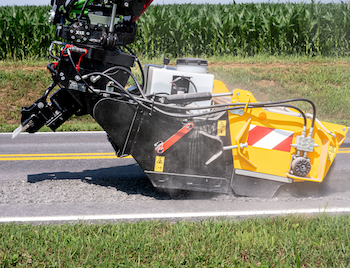

| The machine’s TAB two-piece boom features the JCB Multi-tool mounted on an X12 Steelwrist tilt-rotator. The Multi-tool is comprised of two attachments, a dedicated hydraulic cropper and a sweeper/bucket with integrated dust suppression. |

|

| The Pothole Pro can prepare up to 299 square yards of roadway in a single shift, or 6,540 cubic yards per month and allows the contractor or municipality to cut the defect, crop the edges and clean the hole with one machine. By mechanizing jobs traditionally done by pothole crews the attachment can deliverup to a 50 percent cut in daily costs. |

JCB has developed a highly productive single-machine pothole and patching repair solution to fix potholes permanently, the first time, without the need for labor intensive repair methods or additional expensive machinery.

The Pothole Pro can repair a pothole in less than eight minutes, which is four times quicker than standard methods and at half the cost of current solutions. The machine’s development has been personally led by Lord Bamford, JCB Chairman.

“Potholes are really a scourge; we are fixated on this dreadful problem and I am fixated on finding a solution. We simply cannot allow our road networks to continue to be blighted by potholes,” says Bamford. “JCB’s solution is simple and cost effective and fixes potholes permanently, first time. Once the machine has done its job all the contractor then needs to do is just add asphalt.”

Tests with contractors and municipalities show the JCB Pothole Pro can complete a pothole repair in less than eight minutes – equivalent to 700 potholes per month. With a 25-mph travel speed, the machine can rapidly relocate between sites without additional transport costs.

The JCB Pothole Pro is equipped with a planer mounted on the machine’s rear skid steer hitch. The planer is 24 inches wide, with up to 4.26 feet of side-shift adjustment. This allows the operator to plane a full roadway lane from the curb, without repositioning the machine. Hydraulic tilt and depth control provide a consistent depth for larger patches.

The machine’s TAB two-piece boom features the JCB Multi-tool mounted on an X12 Steelwrist tilt-rotator. The Multi-tool is comprised of two attachments, a dedicated hydraulic cropper and a sweeper/bucket with integrated dust suppression. The 16-inch cropping tool eliminates the need for floor saws or hydraulic breakers, providing a squared off, clean cut to the repair area. The operator then rotates the boom head to bring a 4 foot-wide sweeper/bucket into use to clean up the pothole area, eliminating the requirement for a separate sweeper truck. Material lifted by the sweeper/bucket can be loaded directly into a support truck for rapid removal from site.

The Pothole Pro can prepare up to 299 square yards of roadway in a single shift, or 6,540 cubic yards per month and allows the contractor or municipality to cut the defect, crop the edges and clean the hole with one machine. By mechanizing jobs traditionally done by pothole crews the attachment can deliverup to a 50 percent cut in daily costs. Safety is also improved as the crew does not have to complete the handheld cutting and breaking, eliminating the risk of hand arm vibration syndrome (HAVS).

The Pothole Pro has also been tested and evaluated in North America, most recently at multiple municipalities in Pennsylvania. “Amazed, I was very impressed with how quickly it worked, the speed of the mill head is definitely faster than anything I’ve utilized out on a job site, and the maneuverability was fantastic,” says Neil Stoltzfus, roadmaster of West Earl Township in Pennsylvania. “This would typically have been a three-machine operation and instead the Pothole Pro was able to accomplish the task with one machine, without changing any attachments.”

https://www.jcb.com/en- us/products/wheeled-excavators/hydradig/potholepro